Inventory Reconciliation App for Visual ERP

A time saving tool that systematically tracks, manages, audits and reconciles your Visual inventory and work in process quickly and effectively.

About the Inventory Reconciliation App

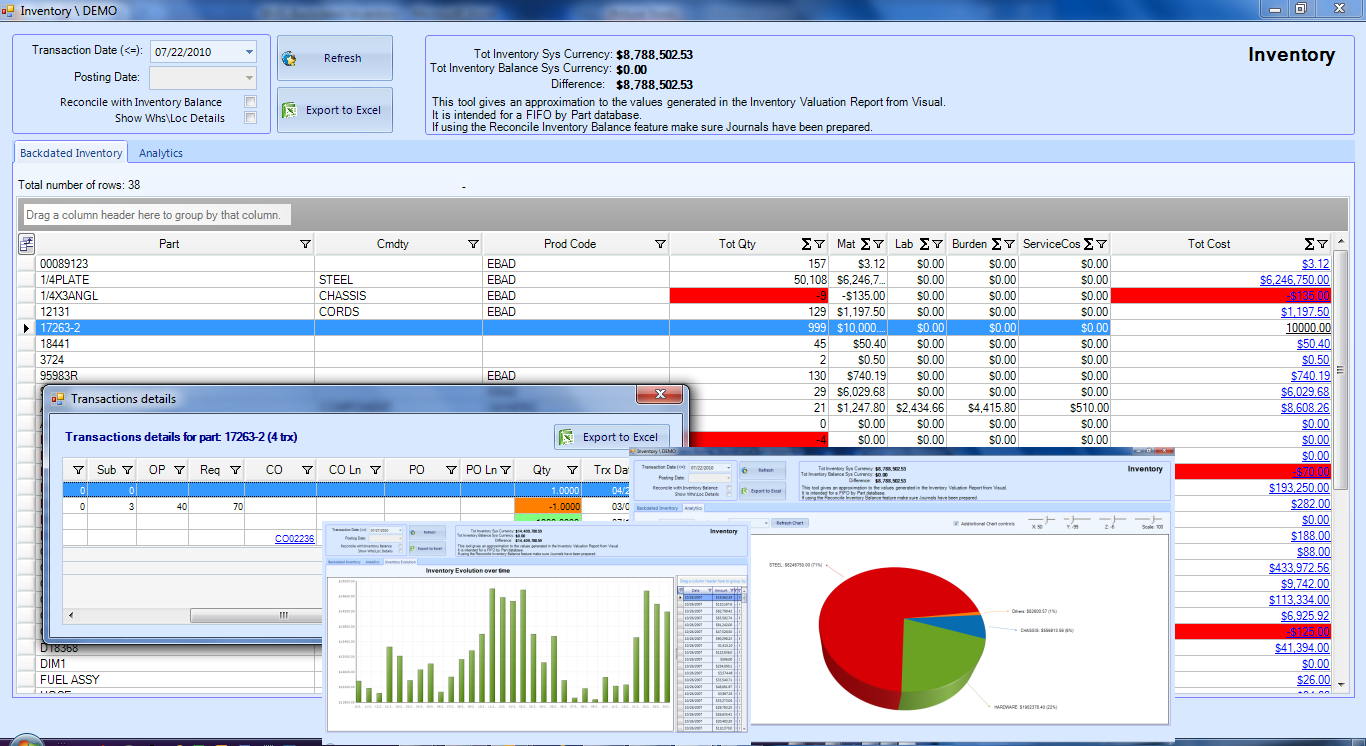

Immediately detect costly variations between your manufacturing inventory and posted records. Track down pesky mistakes and reconcile your inventory quickly and effectively. Problem transactions are clearly indicated for easier review. Navigation is intuitive and straightforward. Includes Visual Inventory courses, standard operating procedures and much more!

This app identifies discrepancies showing transaction details so that you can have a deep understanding of what went wrong and why. It empowers users to find the root cause of inventory issues, and recognize patterns to be able to modify procedures and implement corrective actions effectively. You can filter data, drill-down and track inventory/work in process discrepancies, and easily reconcile inventory/WIP to financial records for current or past periods – all from one screen even if you’re running multiple sites or databases.

Benefits

- Identify costing issues and reconciliation discrepancies by part in seconds

- Streamline your Visual Inventory/WIP reconciliations

- Access your Inventory Valuation as of any point in time

- Capture anomalies immediately at the part and work order level

- Audit your Inventory/WIP/Labor Real Time

- Easily create dashboards to report key metrics that keep you focus on your targets

- Train and retrain your team members with the included library of Visual inventory courses, standard procedures and eLearning Tips.

Inventory Modules:

- Inventory Module: Access the valuation of your inventory as of any date, drill down to transactions, and reconcile actuals to financial records. (Includes trace information where applicable).

- Audits Module: a set of predefined assessments to help you capture potential issues within key areas of the system and proactively take action to fix them before month-end begins.

- WIP Module: Monitor work in process, drill down to transactions (all in one screen) and reconcile actuals to financial records.

- Labor Analytics Module: Perform labor ticket analyses and measure efficiencies by department, resources, employee and more.

- Physical Count Module (Optional): The Barcoding solution processes inventory and is enabled to count from a tablet. Count sheets and Variance analyses are exportable to excel. Contains an Integrated Barcoding label report.

- Trace Tree Module (Optional): Builds Backward/Forward Trace trees and compiles all parts directly or indirectly used or to be used in a top-level work order or finished product.