Trace Tree

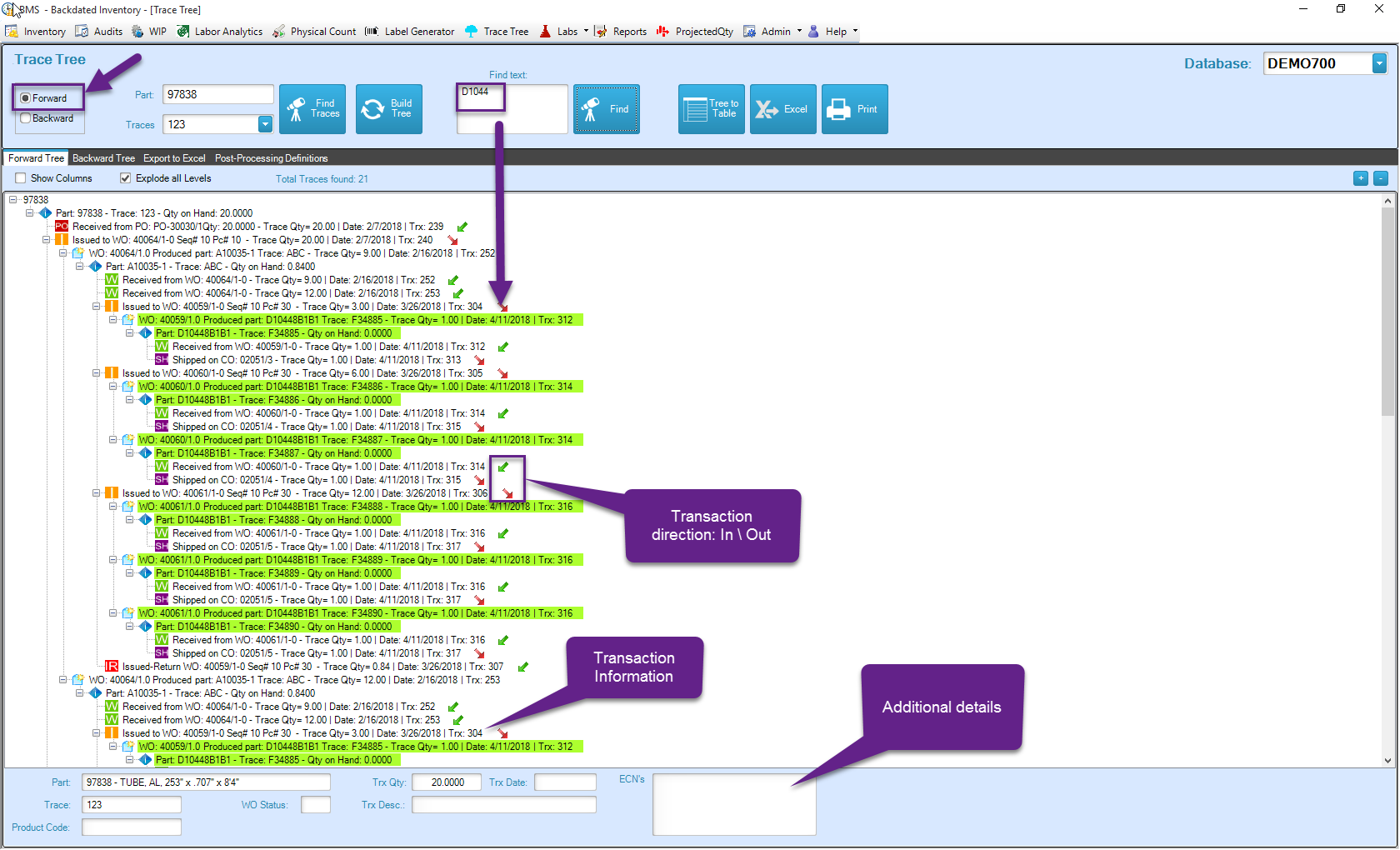

The Trace-tree is a hierarchical data structure that is built based on transactions through multiple iterations.

For traceable parts, the history recorded in the Trace Inventory Transactions is the main source of information for creating the links between the "nodes" within the tree, where for non-traceable parts the Fifo layers of cost (cost distributions) are used for linking all the nodes.

There are 2 directions for building the tree: Forward or Backward.

Forward Tree

In Forward direction, the tree starts with a Part Id and a Trace Id and its logic iterates all the way through until that Part Id and Trace Id are "consumed": either Shipped or Adjusted-Out of inventory.

Main functioning principles

-

Starting with a given Part and Trace, this tree shows all the places (Work Orders, Customer Orders, etc.) where this particular Part Id and Trace were used.

-

The last step of a tree branch (called leaf) is always a transaction that “takes” material out of inventory. In other words, this is the last time this particular part/trace existed in your inventory.

-

Each tree branch could be a result of a long sequence of concatenated transactions involving multiple work orders, purchase orders, adjustments, customer orders, etc.

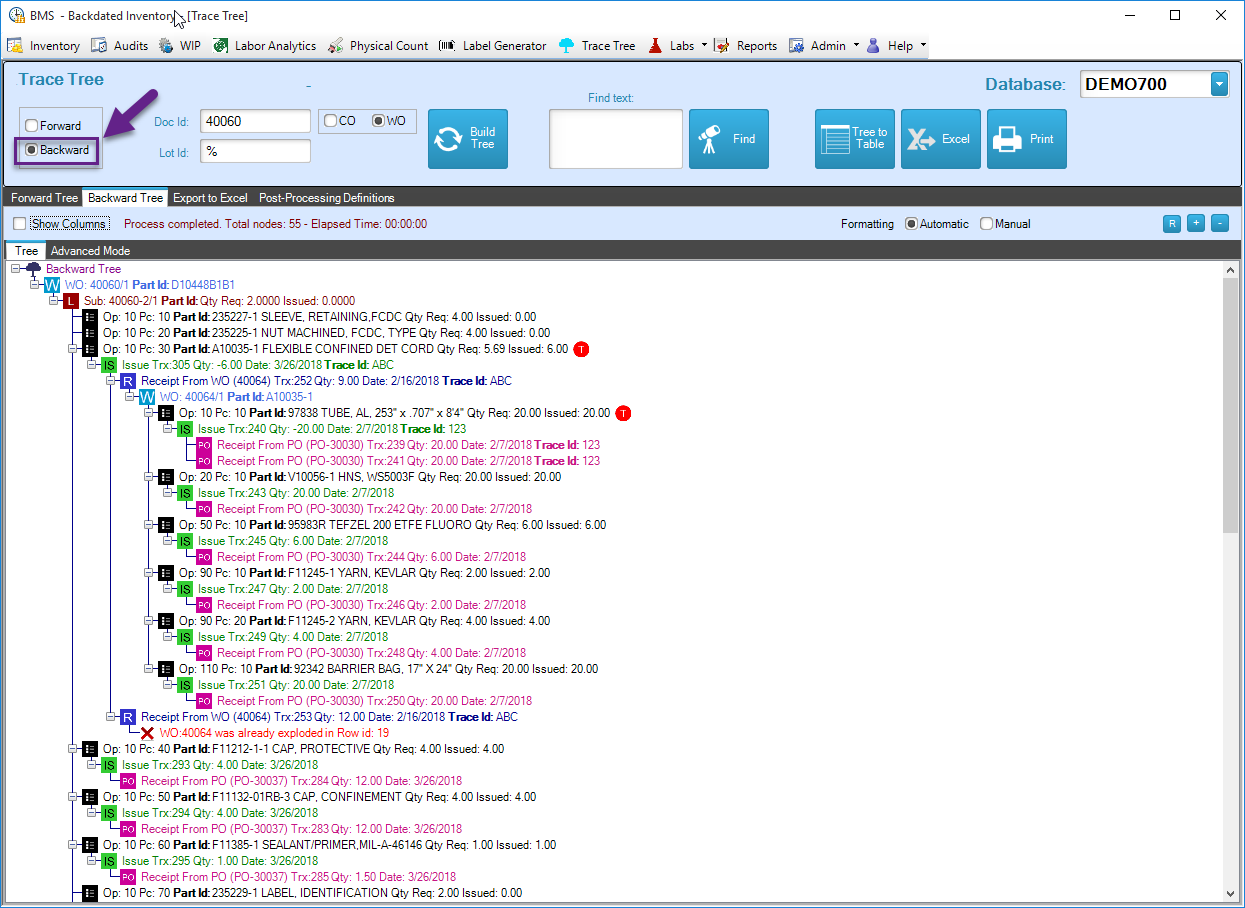

Backward Tree

In Backward direction, the tree starts with a Work Order or Customer Order in the top node and the logic iterates all the way through until it finds the source transactions: a Purchase Order receipt or Adjust-In. These are the only 2 types of transactions that can bring material into inventory.

Main functioning principles

-

Starting with a Work Order or Customer Order, this tree shows all the parts that were issued to it or shipped.

-

The end of each Tree Branch (called leaf) is always a transaction that puts material into inventory (Purchase or Work Order receipt Adjust-In)

-

Each branch could be a result of a long sequence of transactions, typically involving lower level work orders and relevant legs that produced sub-assemblies which were issued to higher level ones until reaching the top job or sales order that initiated the tree.

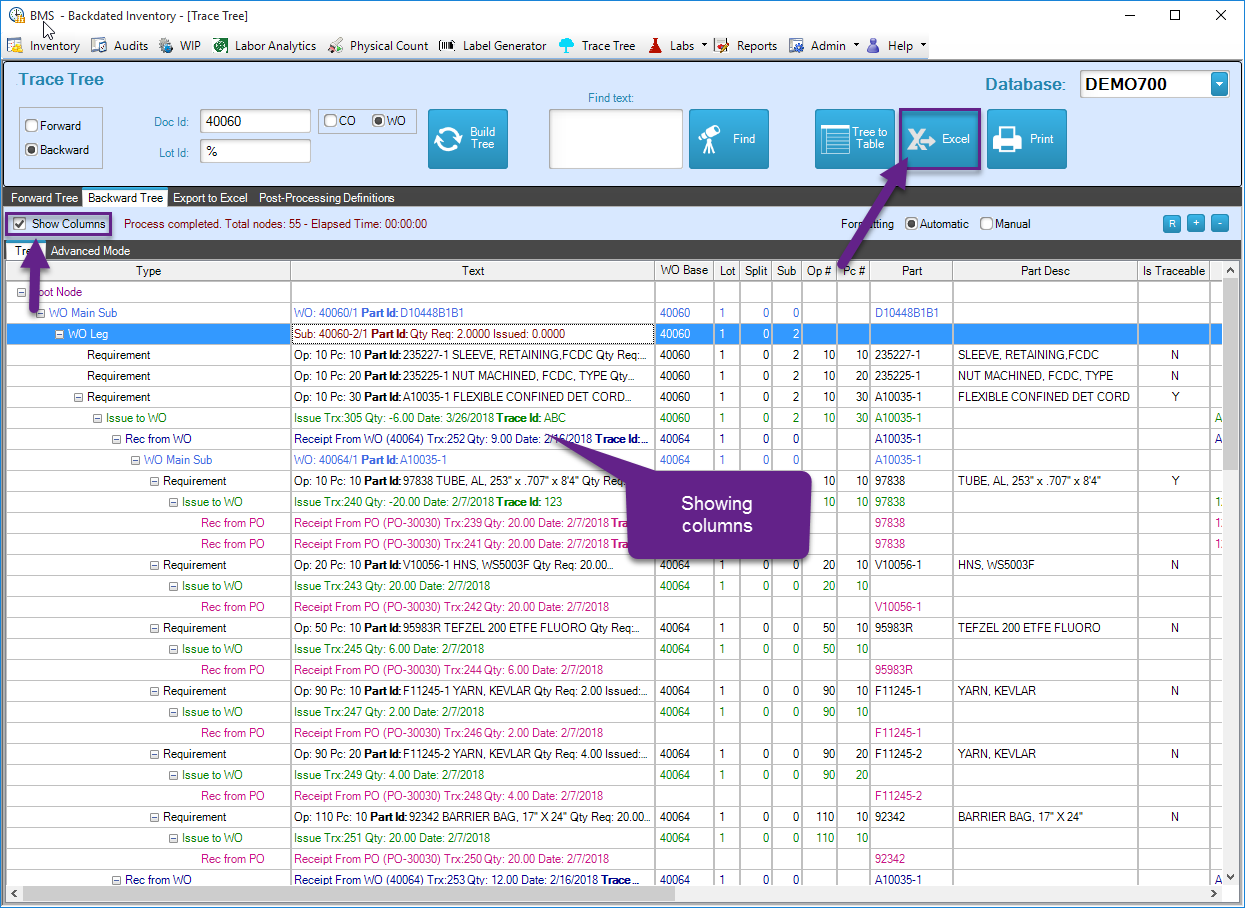

Additional functionality

-

Both types of trees can expose columns with additional information. If even further details from the Visual database are required, they can be added through the Logic Extender

-

All the data within a tree can be exported to Excel in a table-like format.

-

There is also a “find” mechanism that walks the tree from top to bottom facilitating the search of a specific word or text.

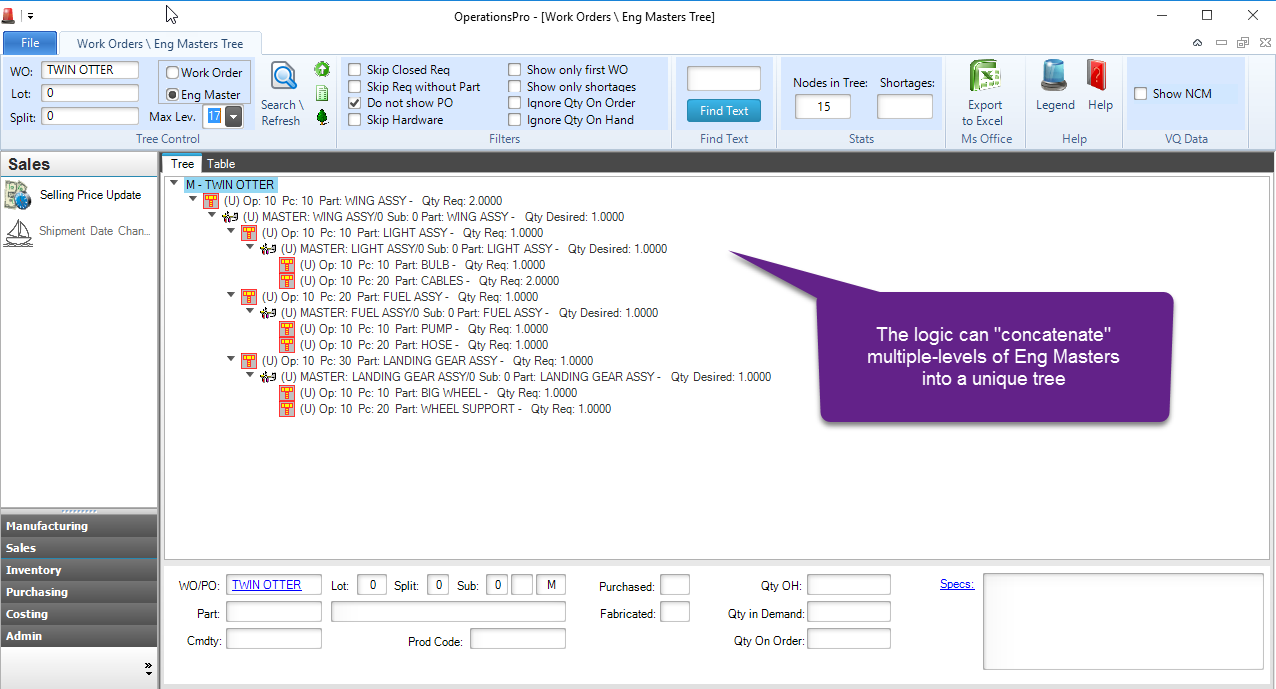

Other types of Tress (custom)

Using a similar iterative process, other types of trees can be built for collecting interrelated data from the Visual database. An example is a tree is built with multiple levels of Work Orders (or Eng Masters). This tree does not use transactional information, instead, the internal logic concatenates multiple levels of Eng Masters (or Work Orders) into a unique master tree linking each document based on a predetermined set of rules (i.e. fabricated Part Ids). The master tree can then be exported to Excel analyzed all at once. Contact BMS365 for further details.